Push lawn mowers are essential tools for homeowners who want to keep their lawns neat and tidy. But like your morning cup of coffee, a mower needs the right care to perform at its best. When something goes wrong, knowing how to troubleshoot and repair it yourself can save money and extend the life of your equipment. In this guide, we’ll walk through common issues, troubleshooting steps, repair instructions, and maintenance tips. Whether you’re a DIY pro or just getting started, these simple and clear steps will help you get your mower back in shape.

Common Issues and Symptoms

Understanding the problem is the first step toward fixing it. Below are some of the most frequent issues people experience with push mowers, along with their symptoms:

1. Mower Won’t Start

Symptoms: Engine cranks but doesn’t turn over, or no sound at all.

Possible Causes: Empty fuel tank, old fuel, faulty spark plug, dirty air filter, or a broken pull string.

2. Uneven Cutting

Symptoms: The grass looks patchy or scalped in places.

Possible Causes: Dull or damaged blade, incorrect wheel height, or blade misalignment.

3. Mower Runs Rough or Stalls

Symptoms: Engine surges or cuts out while mowing.

Possible Causes: Clogged air filter, dirty carburetor, or old fuel.

4. Wheels Falling Off or Loose

Symptoms: Wobbly movement, dragging, or actual wheel detachment.

Possible Causes: Worn-out wheel bolts, broken wheel hubs, or missing retaining pins.

5. Smoke From the Engine

Symptoms: White or blue smoke while running.

Possible Causes: Overfilled oil, oil leak onto the engine, or damaged piston rings.

Troubleshooting Steps

Let’s break down the diagnosis process step-by-step. Think of it like troubleshooting a finicky espresso machine—systematic and careful.

Step 1: Check the Fuel

Use fresh, clean gasoline.

Avoid ethanol-blended fuels when possible.

Empty and refill the tank if the fuel is over 30 days old.

Step 2: Inspect the Spark Plug

Remove the spark plug using a wrench.

Clean it with a wire brush or replace if the electrode is worn.

Make sure the gap is set to the manufacturer’s specs.

Step 3: Examine the Air Filter

Remove the air filter cover.

If it’s paper, replace it. If it’s foam, clean it with soap and water, let it dry, and re-oil lightly.

Step 4: Check Blade and Undercarriage

Disconnect the spark plug before checking the blade.

Tip the mower on its side (air filter up).

Clean debris and check for bent or dull blades.

Step 5: Check Oil Level

Use the dipstick to confirm it’s within the recommended range.

Too much oil can cause smoke and poor performance.

Step 6: Inspect Wheels and Fasteners

Wiggle each wheel. If loose, tighten or replace the fastener.

Look for cracks or damage on plastic wheel hubs.

Repair Instructions

Replacing a Pull String

- Tools Needed:

- Screwdriver

- Socket wrench

- Replacement pull cord

Steps:

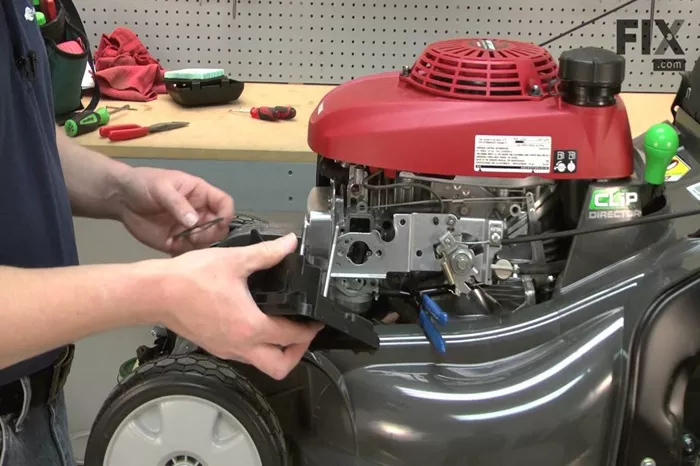

- Remove the engine cover with a screwdriver.

- Carefully take off the recoil starter assembly.

- Remove the broken string.

- Wind the pulley clockwise to add tension.

- Thread new cord through the hole and tie a knot.

- Reattach the handle and reassemble everything.

Fixing a Broken or Loose Wheel

Tools Needed:

- Socket wrench

- Replacement wheel (if needed)

- Retaining pin or bolt

Steps:

- Lift the mower and support it securely.

- Remove the old wheel using a wrench.

- Inspect the axle and clean off debris.

- Install new wheel and tighten the bolt securely.

- Test the wheel for tightness and spin.

Sharpening or Replacing the Blade

Tools Needed:

- Blade removal tool or wrench

- Metal file or bench grinder

- Replacement blade (if needed)

Work gloves

Steps:

- Disconnect spark plug.

- Tip the mower with carburetor side up.

- Use a wrench to remove the blade bolt.

- Sharpen blade with a file or grinder, following original angle.

- If blade is damaged, replace it entirely.

- Reinstall blade securely.

Cleaning or Replacing the Air Filter

Tools Needed:

- Screwdriver

- Replacement filter (foam or paper)

- Soap and water (for foam filters)

Steps:

- Open air filter housing.

- Remove and inspect the filter.

- For foam filters: wash, dry, and oil lightly.

- For paper filters: replace with new.

- Reassemble cover securely.

Maintenance Tips

Regular maintenance keeps your mower running smoothly, just like regular descaling keeps your espresso machine purring.

1. Clean the Deck

After each use, scrape off grass and debris from the underside.

Use a putty knife or stiff brush.

2. Change the Oil

Change engine oil every 25 hours or at least once a season.

Run the mower for a few minutes, then drain the oil while it’s warm.

3. Replace Spark Plug Annually

Even if it seems fine, replace the spark plug each season for easy starting.

4. Store It Properly

Drain the fuel if storing for more than 30 days.

Store in a dry, covered place.

5. Check Bolts and Fasteners

Vibrations can loosen parts. Check everything is tight before each mow.

When to Seek Professional Help

Not all repairs are DIY-friendly. If your mower has any of the following issues, it’s best to call in the pros:

- Persistent starting problems despite replacing spark plug and filter

- Loud knocking or grinding noises during operation

- Severe oil or fuel leaks

- Transmission problems (on self-propelled models)

- Cracked engine block

Trying to fix complex engine or transmission issues without proper tools and training can cause more harm than good.

Conclusion

Fixing a push lawn mower is a lot like perfecting your coffee brewing method—a little attention and maintenance go a long way. By learning to identify common issues, using the right tools, and following simple repair steps, you can keep your mower running smoothly for years. Regular maintenance not only prevents breakdowns but also saves money and extends the life of your mower. So next time your mower gives you trouble, take a breath, grab your tools, and tackle it like a pro. Happy mowing!

Related topics:

- Who Manufactures Ferrex Lawn Mowers

- Who Made Scotts Lawn Mowers

- Why Does My Lawn Mower Start Then Stop?